After training as a machine fitter at Daimler-Benz AG in Stuttgart, he successfully completed his degree in mechanical engineering at the University of Applied Sciences in Esslingen.

As a young engineer, he gained a wide range of experience in various industries, primarily in sales, where he was most recently very successful due to his many years of international experience. He has been Managing Director of Phototherm GmbH since July 2018.

In the beginning, it was scientific research institutes that accepted our products.

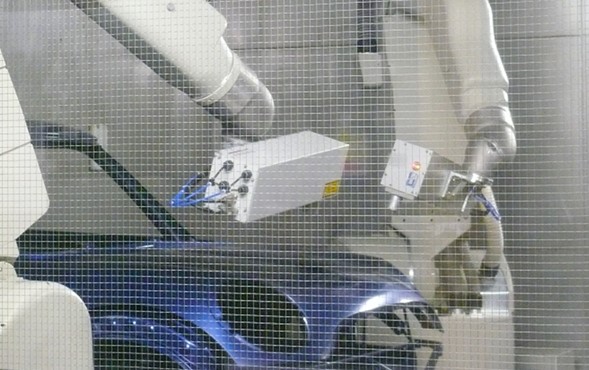

In the meantime, industrial customers from all over the world are using our patented technology and the equipment we have developed and manufactured. Operators of paint shops use our technology to ensure uniform paint distribution during automated painting, thus ensuring compliance with quality standards.

Our customer base covers a wide range of products - from automobiles to steel furniture, electrical cabinets, caravan sheet metal, radiators, kitchen appliances, metal ceilings, building facades and coated frying pans.

In the beginning, it was scientific research institutes that accepted our products.

In the meantime, industrial customers from all over the world are using our patented technology and the equipment we have developed and manufactured. Operators of paint shops use our technology to ensure uniform paint distribution during automated painting, thus ensuring compliance with quality standards.

Our customer base covers a wide range of products - from automobiles to steel furniture, electrical cabinets, caravan sheet metal, radiators, kitchen appliances, metal ceilings, building facades and coated frying pans.

Since its foundation in 1984, our company has been dedicated to photothermal coating measurement - a non-contact and non-destructive determination of the thickness of paint coatings based on thermal waves. The measurement principle is simple and is also known as the photothermal effect.

The photothermal effect has been known for over 100 years. It refers to the effect that materials can absorb optical radiation and convert it into heat.

A laser beam or LED radiation generates a slight heating on the paint surface. The heat flows through the paint layer and experiences a reflection at the base material. The thicker the layer, the longer it takes the heat to travel back through the coating. An infrared sensor determines the travel time and the electronics convert it into thickness. The process also works before baking, i.e. even with wet and powder coatings.

Depending on the application, the entire measurement process is completed after just 0.1 s, so that online measurements can be taken even at high product speeds of up to 200 m/min. The sensor achieves accuracies of up to ± 0.1 µm (ten-thousandths of a millimeter) from a distance of 250 mm for coating thicknesses of 0.005 mm to 0.2 mm. It tolerates distance variations of up to 100 mm.

Since its foundation in 1984, our company has been dedicated to photothermal coating measurement - a non-contact and non-destructive determination of the thickness of paint coatings based on thermal waves. The measurement principle is simple and is also known as the photothermal effect.

The photothermal effect has been known for over 100 years. It refers to the effect that materials can absorb optical radiation and convert it into heat.

A laser beam or LED radiation generates a slight heating on the paint surface. The heat flows through the paint layer and experiences a reflection at the base material. The thicker the layer, the longer it takes the heat to travel back through the coating. An infrared sensor determines the travel time and the electronics convert it into thickness. The process also works before baking, i.e. even with wet and powder coatings.

Depending on the application, the entire measurement process is completed after just 0.1 s, so that online measurements can be taken even at high product speeds of up to 200 m/min. The sensor achieves accuracies of up to ± 0.1 µm (ten-thousandths of a millimeter) from a distance of 250 mm for coating thicknesses of 0.005 mm to 0.2 mm. It tolerates distance variations of up to 100 mm.